- CANT SAVE FILE IN INKSCAPE GCODE EXTENSION HOW TO

- CANT SAVE FILE IN INKSCAPE GCODE EXTENSION WINDOWS 7

- CANT SAVE FILE IN INKSCAPE GCODE EXTENSION DOWNLOAD

But there is no option or setting called "Area radius". I did find Area extension dialog which does have an Area tab. " and "Fill in Tool diameter." Which dialog should we open? There seems to be something missing between "Gcode tools. Then go to Area tab, and fill in Area radius." Could you please explain the following?įill in Tool diameter in the Preferences tab We're using your tutorial which is attached PDF.

CANT SAVE FILE IN INKSCAPE GCODE EXTENSION WINDOWS 7

I'm on Windows 7 and they're on Windows XP.

We're both using version 0.92.1 and both on Windows. I'm trying to help someone use your Gcode tools extensions in Inkscape. Milling speed.svg the lower improvements would increase the total milling time a lot. svg)ĭoes anybody have a good idea or a hint where I should look for a more efficient way to generate milling paths? (One maybe simple implementation to increase processing speed - more in the. Maybe the solution is already implemented somewhere in inkscape or your tool but I couldn't find it.

CANT SAVE FILE IN INKSCAPE GCODE EXTENSION HOW TO

It is not enough to connect all paths because there could be collisions, accordingly there has to be a more intelligent way how to connect a lot of pathes along one main path or sth like this. svg file with different area filling approaches and possibilites to solve or improve it. In commercially available products it is possible to fill areas with "single lines" to reduce this waste of time. When I processed filigrane structures I found that the total milling time for areas is often dramatically increased by the raise and pierce in process after every cnc - path. I am playing around with inkscape, your gcodetools plugin and a mill to cut 2D profiles into wood.

CANT SAVE FILE IN INKSCAPE GCODE EXTENSION DOWNLOAD

Next, download a third party open source program Slic3r.SVG File on the website, edit the depth of the shape, and export the same to. This is an online website that converts the.Set the orientation source and nature of the extrusion that needs to be created.

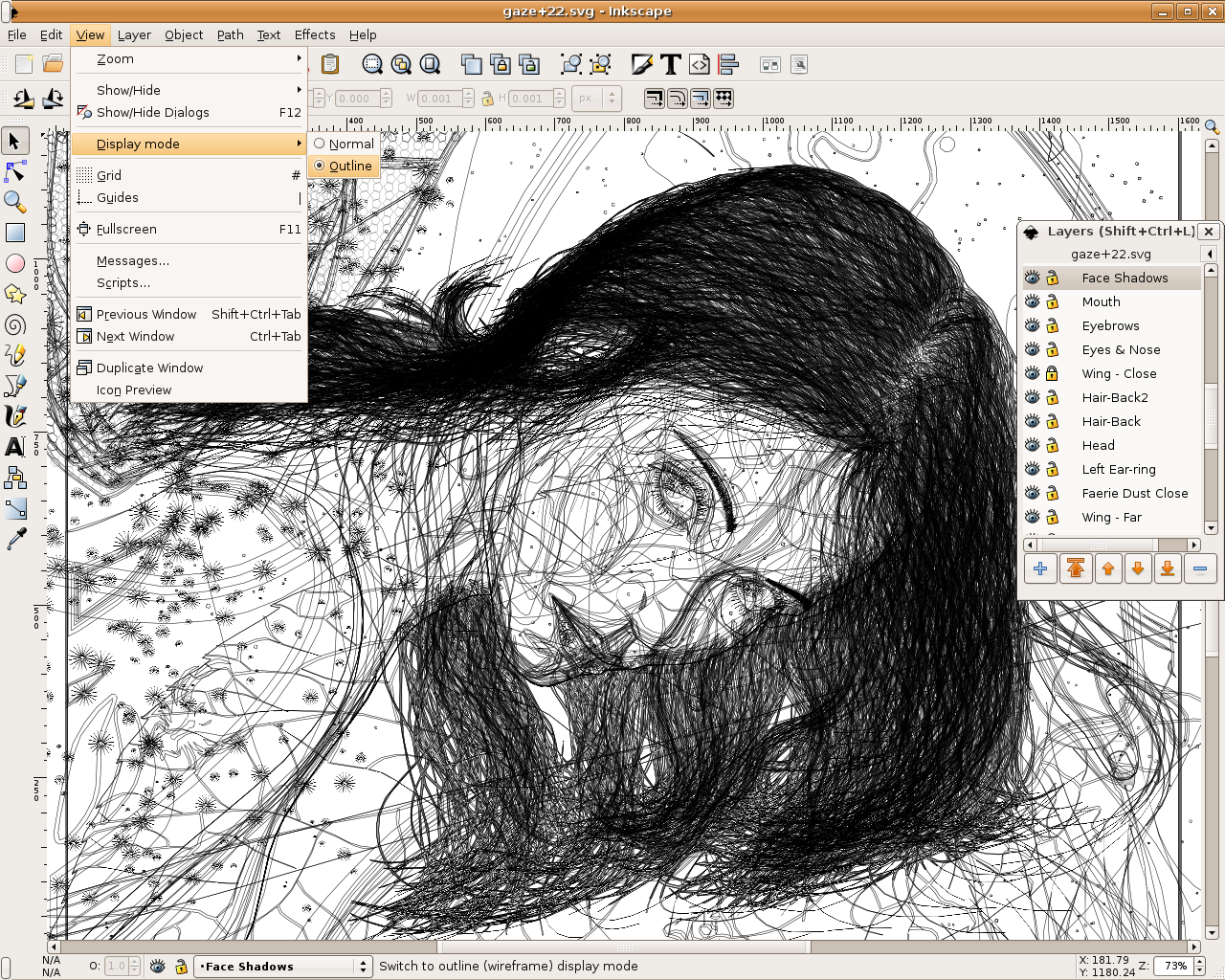

For this, go to Extensions> g-code tools> Orientation Points. Next, we need to enter the orientation source and points of the shape to be cut within the 3D printer.The user can modify the settings from the boxes. Similarly, different boxes will be created with the other layers as well.The user can click on the box and edit the settings from there if needed. A green box will appear for the 1 st layer that specifies preferences for the G-code.This method has to be done for every individual layer one by one. Select CONE from the dialog box and click Apply.

These are options given to the user to select the tool for the way of cut they want. Now, go to Extensions > G-code Tools and select Tools library.The shapes should be adjusted in such a conduct that they appear as a 3D shape with hard edges.Again add a layer and copy the same shape on this layer.Create a new layer by going to Layer> Add a layer.Still, without utilizing any external program, Inkscape is capable to create G-code for machine purposes.įollowing are the steps to create G-code in Inkscape:. This technique is proficient but, it may sometimes be a confusing or time-consuming process for the users. So, to use G-code for 3D printers we need to create a 3D effect to get the desired results. Since we all know that Inkscape is not a 3d program.

0 kommentar(er)

0 kommentar(er)